Beer industry applications

Keyword:

Beer industry applications

Category:

Details

|

Project Name: Energy-Saving Solution for the Beer Industry Project Overview: The processes with currently high hot water demands are: |

|

| Carbon Reduction and Economic Analysis | |||

| Before Renovation | Heat Source Type | / | Purchased Steam |

| Required Thermal Power | kW | 1800 | |

| Steam Consumption | Tons of Steam/h | 2.6 | |

| Unit Price | Yuan/ (ton of steam) | 320 | |

| Operating Time | h | 8000 | |

| Annual Operating Cost | Ten Thousand Yuan | 658.3 | |

| After Renovation | Heat Source Type | / | Heat Pump Generated Steam |

| Steam Consumption | kW*h/(ton of steam) | 320.0 | |

| Total Electricity Consumption | kW | 822.9 | |

| Electricity Price | Yuan/(kW*h) | 0.75 | |

| Annual Operating Cost | Ten Thousand Yuan | 493.7 | |

| Economic Efficiency | Annual Carbon Reduction | Tons/Year | 4033.6 |

| Carbon Trading Price | Yuan/Ton | 58 | |

| Estimated Carbon Reduction Benefits | Ten Thousand Yuan/Year | 23.4 | |

| Annual Cost Savings | Ten Thousand Yuan/Year | 164.6 | |

|

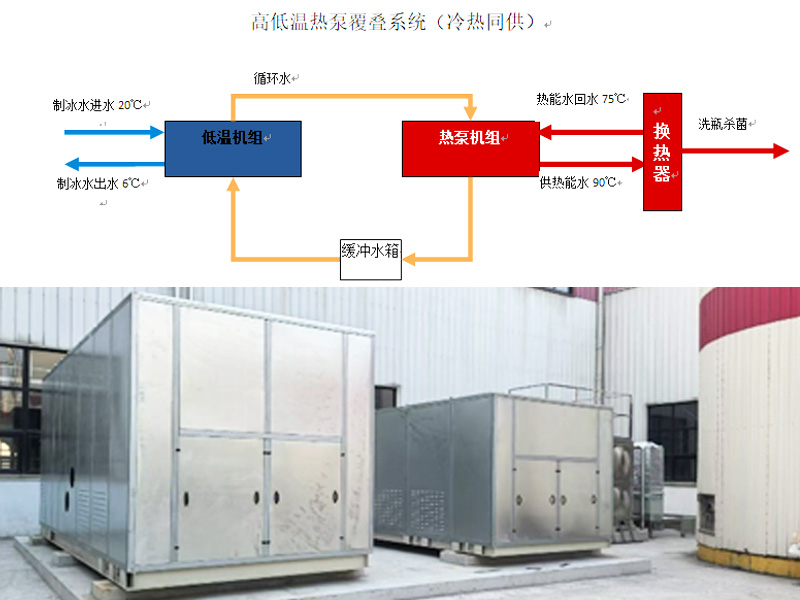

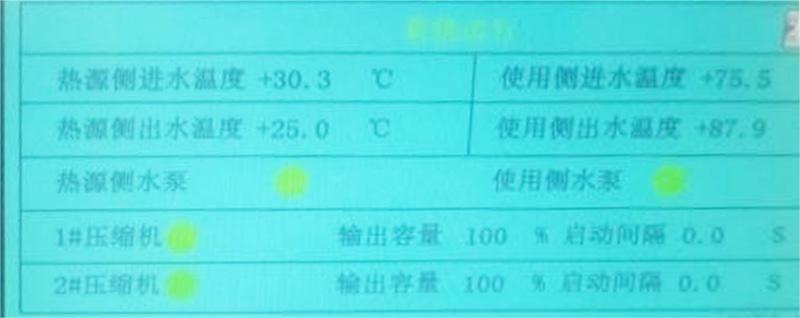

Project Name: Simultaneous Heating and Cooling Supply Project Overview: Cooling: Producing ice water or deoxygenated water; Heating: Providing heating for bottle washing and sterilization in the packaging workshop |

|

|

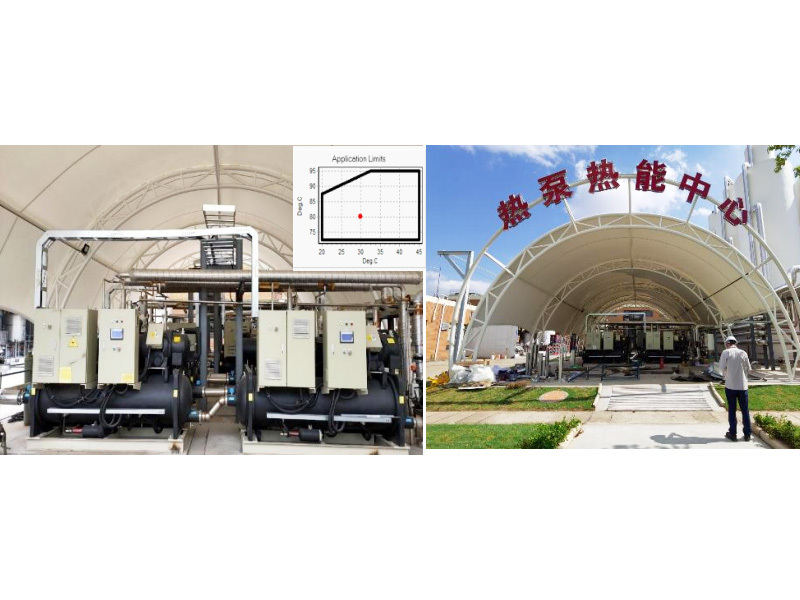

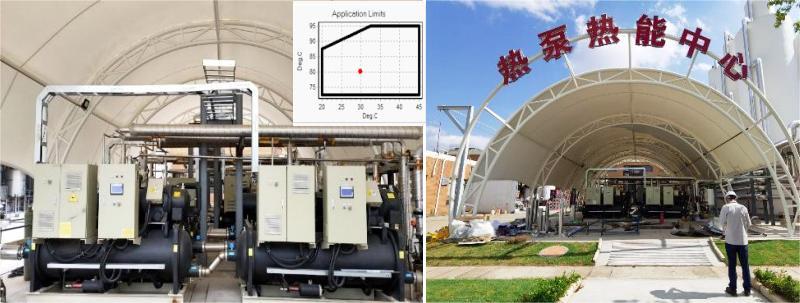

Project Name: Waste Heat Recovery from Ammonia Refrigeration Unit Condensation Project Overview: A certain internationally renowned brewery: |

|

Service Hotline:

Tel:+86-020-89859431

Mobile:+8613129309431

Email:pelopsbox@163.com

Address: No. 11, Kaifang Avenue, Huangpu District, Guangzhou, Guangdong Province, China, 6th floor, South China Institute of Industrial Technology, Zhejiang University

Room 3008, Building D, SOHO Modern City, Chaoyang District, Beijing, China

No. 588, Hongqiao North Road, Xindai Town, Jiaxing City, Zhejiang Province, China