Brewing application

Keyword:

Brewing application

Category:

Details

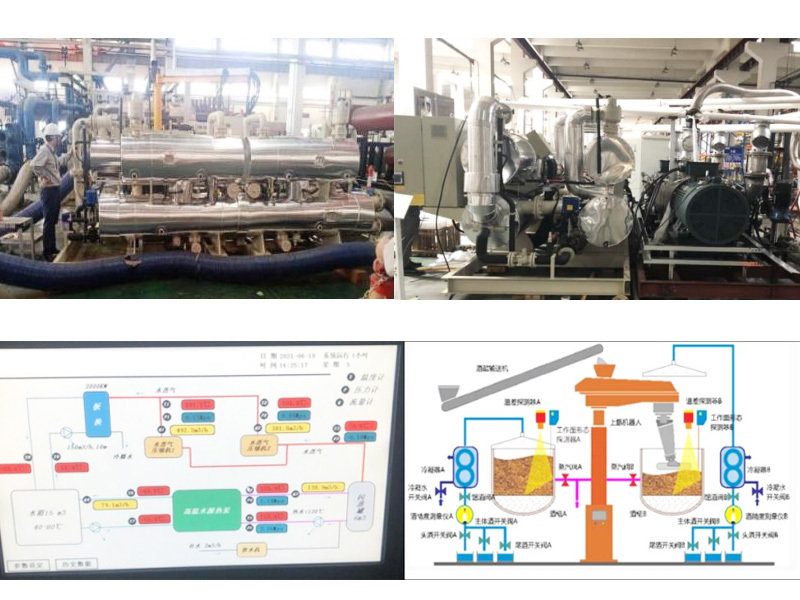

Project Name: Sichuan Distillery

Project Overview: Recovering and condensing the 60-70℃ distiller steam generated by the steam still to produce 100-120℃ low-pressure steam

Solution: Low-pressure steam heat pump unit, utilizing the customer's 60-70℃ waste heat to produce 100-120℃ steam

Investment Benefits: Saving nearly 1.5 million yuan/year, reducing steam purchase by 8250 tons/year

| Carbon Reduction and Economic Analysis | |||

| Before Renovation | Heat Source Type | / | Purchased Steam |

| Required Thermal Power | kW | 1350 | |

| Consumption | tons of steam/h | 1.9 | |

| Unit Price | yuan/(ton of steam) | 320 | |

| Operating Time | h | 5000 | |

| Annual Operating Cost | Ten thousand yuan | 308.6 | |

| After Renovation | Heat Source Type | / | Heat Pump Generated Steam |

| Steam Consumption per Ton | kW*h/(ton of steam) | 282.1 | |

| Total Power Consumption | kW | 544.1 | |

| Electricity Price | yuan/(kW*h) | 0.7 | |

| Annual Operating Cost | Ten thousand yuan | 190.4 | |

| Economic Efficiency | Annual Carbon Reduction | tons/year | 2079.4 |

| Carbon Trading Price | yuan/ton | 58 | |

| Estimated Carbon Reduction Revenue | Ten thousand yuan/year | 12.1 | |

| Annual Cost Savings | Ten thousand yuan/year | 118.2 | |

Service Hotline:

Tel:+86-020-89859431

Mobile:+8613129309431

Email:pelopsbox@163.com

Address: No. 11, Kaifang Avenue, Huangpu District, Guangzhou, Guangdong Province, China, 6th floor, South China Institute of Industrial Technology, Zhejiang University

Room 3008, Building D, SOHO Modern City, Chaoyang District, Beijing, China

No. 588, Hongqiao North Road, Xindai Town, Jiaxing City, Zhejiang Province, China